Introduction of New Material for Concrete Technology

Hasber Chemical introduces a novel mix design methodology for activated high-calcium fly ash concrete (AHFAC) using a rational approach. This method is user-friendly, akin to standard admixtures, making it accessible for various applications.

Enhanced Strength with Hasber Chemical

The Hasber Chemical solution increases the strength of concrete with a high volume of fly ash. It can replace up to 40% of Ordinary Portland Cement (OPC) with any cementitious material, including fly ash, GGBS, or metakaolin. The recommended use of Hasber Chemical in concrete is a minimum ratio of 0.7% of the total cement material (OPC + PFA + GGBS).

The Importance of Sustainable Concrete

Concrete is responsible for around 70% of industrial CO2 emissions, prompting the development of green concrete as a sustainable alternative. Hasber Chemical, by incorporating environmentally friendly materials like fly ash, lime powder, metakaolin, and Ground Granulated Blast Furnace Slag (GGBS), offers a solution that reduces carbon emissions and enhances concrete properties.

- Fly Ash: Replaces cement, improving workability and durability.

- Lime Powder: Stabilizes mixtures and helps capture CO2.

- Metakaolin: Improves strength and resistance to chemical attacks.

- GGBS: Enhances corrosion resistance and reduces reliance on cement.

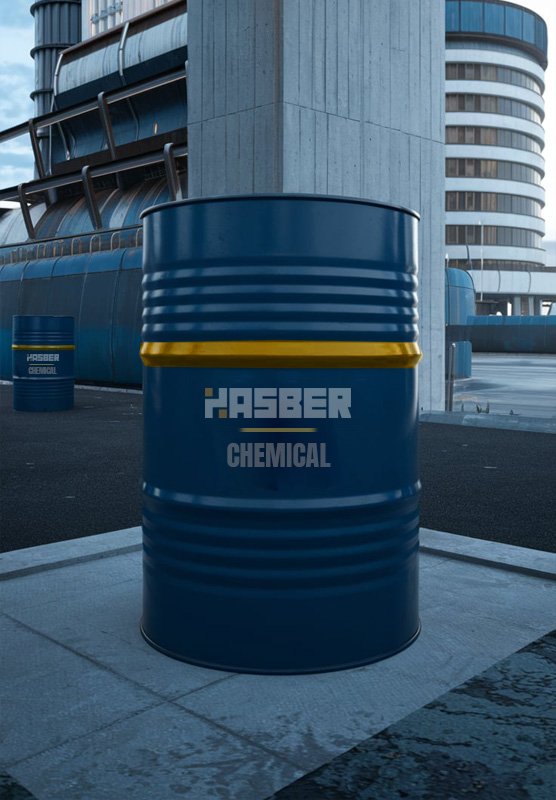

Composition of Hasber Chemical

Hasber Chemical is a cutting-edge, eco-friendly binder formulated with sustainable and high-quality materials to enhance the performance of concrete. Its innovative composition includes:

- Approximately 50% of Hasber Chemical is made from recycled materials, such as silica sourced from ground-up glass and waste products from the pharmaceutical industry.

- Acts as a catalyst in concrete, reacting with CO₂ and water to form iron carbonates, a highly durable and stable compound that improves concrete’s structural integrity.

- Hasber Chemical allows for the substitution of up to 40% of traditional cement with alternative materials like high-calcium fly ash, Ground Granulated Blast Furnace Slag (GGBS), and metakaolin, promoting a sustainable approach to concrete production.

- Designed to be 100% VOC-free and free of hazardous air pollutants, Hasber Chemical is safe for use in both residential and commercial applications.

Benefits of Hasber Chemical

The use of Hasber Chemical in concrete provides numerous advantages that contribute to both structural performance and environmental sustainability:

- Increases the compressive strength of concrete, especially in mixtures with a high volume of fly ash.

- Reduces water permeability and improves compaction, making concrete more resistant to environmental factors.

- Acts as a carbon sink by absorbing CO₂ during the hardening process, helping to reduce the concrete industry’s carbon footprint.

- Offers a “green” alternative to traditional Portland cement, which is a significant source of global carbon emissions.

- Manufactured using recycled materials, thus promoting waste reduction and supporting a circular economy.

- Structures made with Hasber Chemical require less maintenance over time due to increased durability, reducing long-term costs and environmental impact.

- Provides a smoother, more workable mix with a controlled setting time, making it easier to handle and ideal for diverse construction applications.

- Reduces hydration cracking and includes self-healing properties, enhancing the concrete’s lifespan.

- Although Hasber Chemical has a slightly higher initial cost, it allows for a reduction in cement use and improves durability, leading to cost savings in the long run.

- Less material is needed due to its high compressive strength, which results in a lighter structure without compromising quality.

Trial Results with Hasber Chemical

M25 Grade Concrete Trial

Days

Day 1

Day 3

Day 7

Day 28

Strength (MPa)

| 8.54 |

| 16.9 |

| 22.66 |

33.45 |

Chemical Specifications

Test Parameter

| Physical Appearance |

| pH |

| Specific Gravity |

| Chloride |

Sulphur

Specification

| Colorless to Slight Pale Orange Liquid |

| min.8 |

1.24 to 1.33

0.01%

0.03%

Testimonials

"HASBER Chemical has been an exceptional partner for us. Their high-quality chemicals and customized formulations have significantly improved our manufacturing processes. The team’s expertise and commitment to quality are unmatched."

– Priya R.

Production Head, Manufacturing Solutions Ltd.

"The products we source from HASBER Chemical are consistently reliable and effective. Their attention to detail and focus on providing safe, high-quality chemical solutions have made a real difference in our operations. We highly recommend their services."

– Mark L.,

CEO, Industrial Coatings Inc.

"HASBER Chemical’s innovative approach and extensive range of chemical products have helped us optimize our formulations. Their team is knowledgeable and responsive, always ready to offer guidance and support. We’re grateful to have them as a trusted supplier."

– Sara M.

Senior Chemist, GreenTech Labs

"Our experience with HASBER Chemical has been outstanding. Their commitment to sustainable, high-performing products aligns perfectly with our values. Their expertise and product quality have been invaluable to our success."

– Rajiv K.

Director of Research, Eco-Industries Pvt Ltd.

"Working with HASBER Chemical has been a game-changer for us. Their customized solutions and high-quality materials have streamlined our processes and enhanced our product quality. Their team is always professional and responsive, making them a valuable partner."